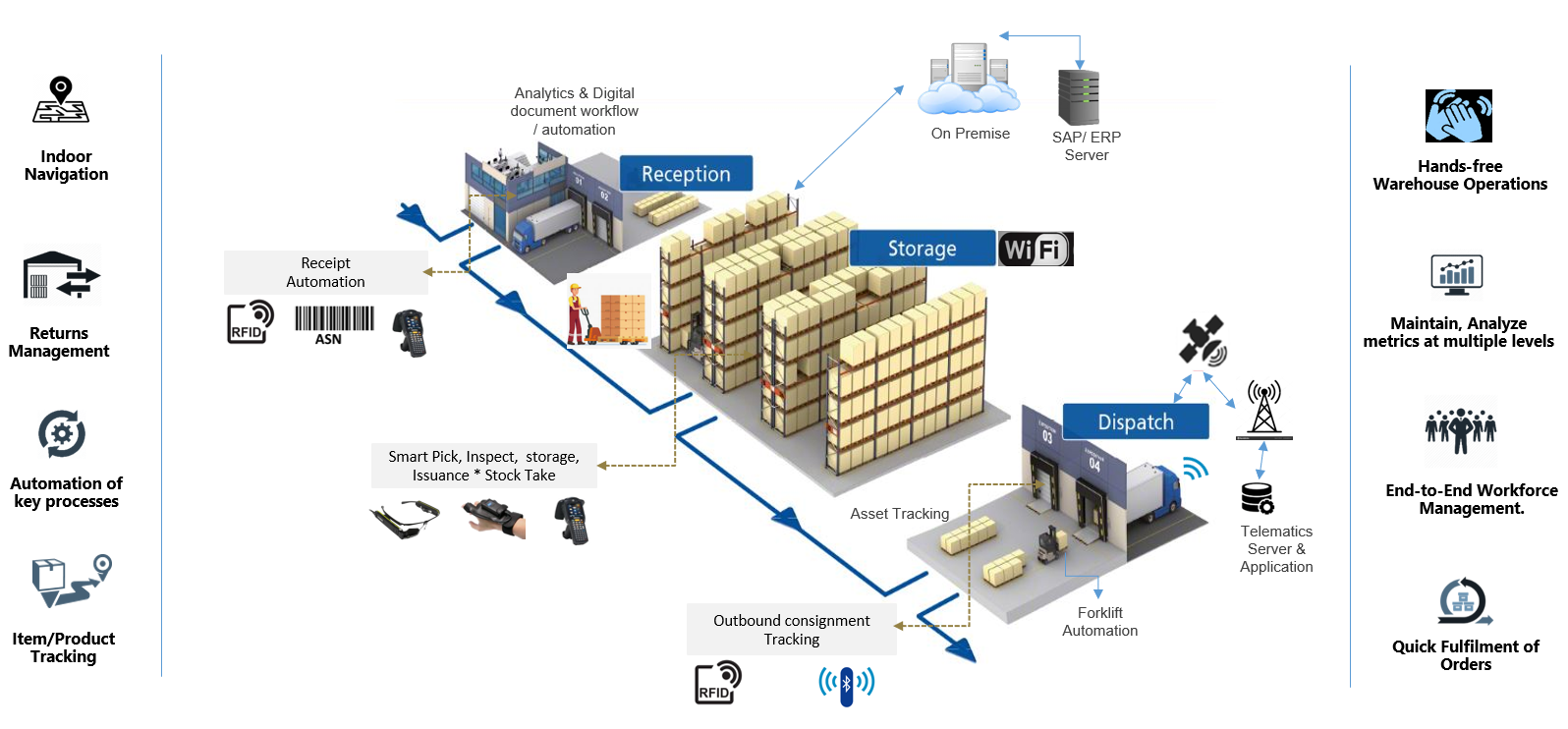

Warehouse digitalisation is critical to the success of any organisation. We are technology agnostic when it comes to warehouse digitalisation. We implement fit for purpose warehouse management solutions as per the client needs and requirements. We do a detailed diagnostic study prior to any implementation.

Warehouse Digitalisation: A Game-Changer for Mining Companies

Digitalisation has become a game-changer for many industries, and the mining sector is no exception. With the rise of technology, the traditional warehousing system has been replaced by a more efficient and cost-effective warehouse digitalisation.

Benefits of Warehouse Digitalisation

- Improved Efficiency: Digitalisation of a warehouse can help in automating and streamlining various warehouse processes, resulting in increased efficiency. With the help of digitalisation, the inventory management process can be done in real-time, reducing the time taken for data entry and updating inventory levels.

- Increased Productivity: With the integration of technology, the productivity of the warehouse can be increased substantially. Automated warehouse systems ensure that products are picked, packed, and shipped accurately and efficiently, reducing the time taken for manual labour and reducing the chances of errors.

- Cost-Effective: A digitalised warehouse system reduces the need for manual labour, thereby reducing the cost associated with it. The automation of processes and use of technology can help in optimising inventory levels, reducing the need for excess inventory and storage costs.

- Enhanced Visibility: Digitalisation of a warehouse helps in providing enhanced visibility into the inventory levels and order fulfilment process. This, in turn, helps in reducing the lead time, improving customer satisfaction, and enhancing the overall performance of the warehouse.

SmartOps Step-by-Step Process for Digitalisation of a Warehouse

- Evaluating the Current System: The first step in the digitalisation process is to evaluate the current warehouse system. Identifying the areas that require improvement and determine the technology that can be implemented.

- Choosing the Right Technology: Selecting the right technology is a critical step in the digitalisation process. We help you choose a technology that can integrate with the existing system, has the potential for scalability, and aligns with the company's goals.

- Developing a Roadmap: A roadmap should be developed, outlining the implementation of the technology and the process involved in it.

- Integration: The chosen technology should be integrated with the existing system, and employees should be trained in using it.

- Continuous Improvement: Continuous improvement should be a part of the digitalisation process. The system should be monitored and evaluated regularly to identify areas of improvement.

Warehouse Digitalisation Benefits for Mining Companies

Mining companies are known to have a vast and complex supply chain system, and warehouse digitalisation can significantly benefit them. Some of the benefits include:

- Real-time Visibility: Real-time visibility of inventory levels and order fulfilment can help mining companies to manage their supply chain better, ensuring timely delivery of materials to the mining site.

- Improved Safety: Warehouse digitalisation can help in improving safety by automating the hazardous material handling process and reducing the need for manual labour.

- Enhanced Efficiency: The automation of the warehouse process can help in reducing the time taken for manual labour, improving the overall efficiency of the warehouse.

- Cost Savings: Warehouse digitalisation can help mining companies to reduce the cost associated with excess inventory and manual labour, resulting in cost savings.

Our implementation of a Digital Warehouse Solution incorporates:

- Warehouse Management

- Quality Management

Warehouse Management

SmartOps can implement the following Warehouse Management modules.

- Inbound Process

a. Inbound Deliveries GR Process

b. Put away in Respective Warehouse Bins

c. RF Devices for automatic Goods Receipts / Goods tracking/ Goods Issues

- Outbound Process

a. Picking Strategy

b. Picking against Outbound Deliveries

c. Print Picking Label

d. Packing Shipping

e. Vendor Returns

- Physical Inventory Cycle Counting

- Reports, Alerts and monitoring

a. Reports related to stocks

b. Alerting about ware house movements

c. Monitoring the stocks and movements

Quality Management

SmartOps can implement the following fucntionalities within Quality Management

- Quality Control

- Quality Notifications

- Quality Inspection

Quality Control

Following functionalities can be implemented

- Update of the quality level based on the inspection results

- Usage of control charts to control the characteristic values

- Update of the vendor evaluation for the procurement process

- Active quality control ensures the constant quality of the processes and products

Quality Notifications

The following functionalities can be implemented

- Customer complaints

- Complaints against vendors

Quality Inspection

Following functionalities can be implanted