Operational improvement refers to the process of enhancing the effectiveness and efficiency of an organization's operations. It involves analysing the existing processes, identifying areas of improvement, developing a plan, and implementing changes. The goal is to streamline the workflow, increase productivity, reduce costs, and improve the quality of output.

Operational improvement refers to the process of enhancing the effectiveness and efficiency of an organization's operations. It involves analysing the existing processes, identifying areas of improvement, developing a plan, and implementing changes. The goal is to streamline the workflow, increase productivity, reduce costs, and improve the quality of output.

SmartOps improve the way organisations work by making them more efficient, productive, and effective. Our technique is centred around development and implementation of business improvement programs focusing on processes, systems, and people.

The Detailed Process of Operational Improvement in Any Organisation

Step 1: Analysis

The first step in any operational improvement strategy is to analyse the current state of operations. This includes identifying the current processes, the resources utilized, the technologies and tools used, the output quality, and the costs associated. This step can be conducted through process mapping, surveys, interviews, and benchmarking to assess the gaps.

Step 2: Identifying Opportunities

The next step is to identify opportunities for improvement based on the analysis conducted in the first step. These opportunities could be in the form of reducing operational costs, optimizing processes, improving product or service quality, reducing lead times, or increasing productivity.

Step 3: Developing an Improvement Plan

The third step is to develop an improvement plan that outlines the changes required to achieve the identified opportunities. The plan should be specific, measurable, achievable, relevant, and time-bound (SMART) and consider the people, processes, and technology required to implement the changes. The plan should also address the risks associated with the proposed changes.

Step 4: Implementation

The fourth step is to implement the improvement plan. The implementation should be conducted in a controlled manner to minimize disruptions to ongoing operations. The implementation team should monitor progress and address any issues that may arise.

Step 5: Monitor and Continuously Improve

The final step is to monitor the implemented changes to ensure that the desired outcomes are achieved. This involves conducting regular performance reviews, collecting feedback, and analysing the results. The organization should continuously improve the implemented changes to maintain a competitive edge.

Our range of proven methodologies include:

- Management Operating Systems & Behavioural Change

- Process Improvement ( Lean Six Sigma, Constraint Management)

Management Operating Systems (MOS)

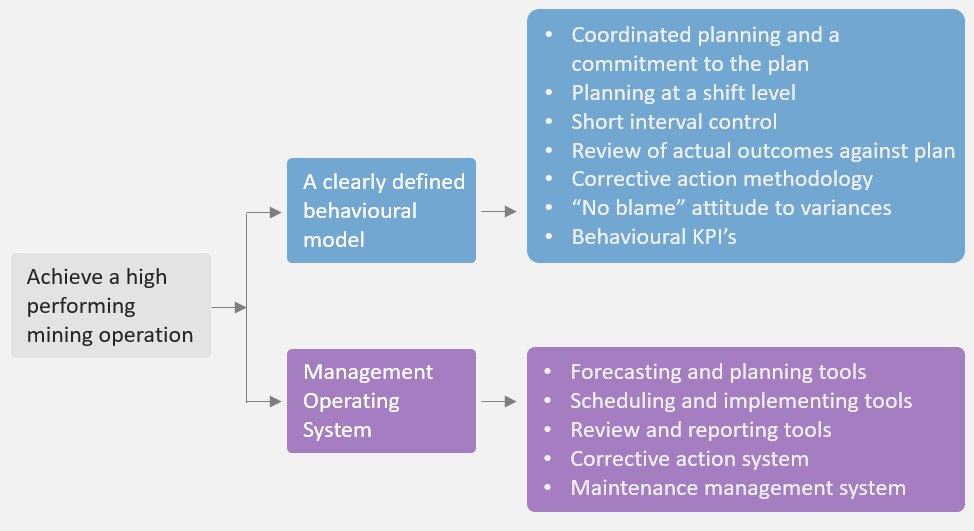

The Management Operating System is a set of management tools that supports operational excellence in an operating or project environment. The tools on their own do does not deliver high performance but they work in conjunction with effective processes and appropriate management behaviours to create a high-performance operation.MOS is a structured approach to managing an organisation that helps streamline operations, improve efficiencies, reduce costs and enhance profitability. This system offers a holistic approach to managing the entire organisation, encompassing all aspects of operations from people to processes, tools and techniques.

Management Operating System (MOS) is designed to deliver consistent work processes and controls across all areas of the operation. The intention is that the controls and processes support and drive the underlying behaviour of active management and continuous improvement. This is achieved by a system of controls (tools that drive work processes) that are used to Forecast, Plan, Schedule, Implement, Report and Review all work. As result the work is done in more predictable and disciplined manner.

The approach also recognises that unexpected or unplanned events do happen (as with any operation) and so a process for identifying, quantifying, and addressing variances is incorporated into the MOS. Managing variance is another key underlying behaviour required in any efficient and high performing operation. SmartOps MOS approach is bundled with our Integrated Operational Software to make it more sustainable. White board and spreadsheet driven MOS has proven to be unsustainable. Our Approach is Digitally driven MOS (dMOS)

MOS offers several benefits that can transform your organisation, including:

- Increased efficiency: MOS helps streamline operations, reducing waste and enhancing efficiency, resulting in increased productivity.

- Improved quality: The system focuses on quality control and process improvement, resulting in fewer errors, reduced downtime and improved product quality.

- Cost savings: MOS identifies areas of cost reduction, eliminates wasteful processes and enhances productivity, resulting in significant cost savings.

- Enhanced customer satisfaction: MOS helps streamline processes, enabling quicker delivery and improved customer service, resulting in enhanced customer satisfaction.

- Improved employee engagement: MOS encourages employee participation, resulting in better communication, motivation and collaboration, resulting in a positive work environment.

SmartOps process of implementing MOS in an organisation is as follows:

- Assess current systems and processes: Identify current processes, systems and procedures, including strengths, weaknesses and areas for improvement.

- Define objectives: Define the key objectives and goals of the MOS, aligning them with the organisation's vision and mission.

- Design MOS framework: Develop a framework for the MOS that aligns with the organisation's structure and objectives.

- Develop MOS procedures: Develop procedures and guidelines for implementing the MOS, including how to train employees and manage change.

- Implement MOS: Implement the MOS system, with regular monitoring and performance evaluation to ensure the system is working effectively.

- Continuously improve: Continuously improve the MOS by gathering feedback, identifying areas for improvement, and making changes to the system.

By implementing a Management Operating System, an organisation can achieve significant benefits, including increased productivity, reduced costs, improved customer satisfaction and enhanced

Process Improvement

To develop and implement effective processes, proven methodologies are used depending on the environment and client requirements. These include:

- Process requirement to identify and deliver customer outputs.

- LEAN Six Sigma with a focus on identifying and eliminating waste and lost time

- Constraints & gap management to improve process flow and efficiency

- Process driver management using performance data to drive decision making and effective behaviours

Process Requirements:

- Effective process improvement starts with defining the requirements of a processes with the requirements clearly defined and agreed process can be improved in a dynamic way that enables it to adapt as the business changes.

Constraints Management:

- In most organisations delivering a final customer outcome requires work to progress through several internal processes. Each of these processes will have internal customer and suppliers with their respective requirements, plus a handover point.

- Aligning interdependent processes in terms of requirements and importantly capacity (for putting through work) is critical to minimise cost, meet delivery dates, and deliver the desired quality standards.

- Constraints management is the process where process interdependencies, capacities and handover points are controlled to deliver the most effective outcomes for both the business and its customers.

Process Quality Management:

- In Process need to be lean and efficient with value adding steps and minimal waste, such as re-work and lost time

- Understand what waste and lost time are

- Determine how the process steps add value

- The characteristic of the process such as high or low work volumes plus repetitive/transactional, batch or project (unique) work will determine the type of quality management control that will be most effective:

- For high volume, high repetitive and transactional or continuous processes performance metrics can be used to manage efficiency, quality and cost through a standards-based planning and dashboard (type) application for control and review.

- For low volume and batch or project processes estimate based approach may be used for planning with short interval control tools used to manage the work and a variance review process to drive improvement.

- Quality can be defined as meeting the customers’ requirements. Knowing what the requirements are (previous slide) and managing the process outputs to satisfy the requirement will ensure that quality is met. This requires a management system that provides the measurement and control elements to deliver the desired outputs.

In summary, operational improvement is a critical process for any business that aims to improve efficiency, reduce costs, and increase productivity. The detailed process involves analysing the current operations, identifying opportunities for improvement, developing an improvement plan, implementing changes, and monitoring the outcomes. A well-executed operational improvement strategy can significantly impact an organization's success.